|

|

|

|

|

The Japanese Path To Maintenance Excellence.By Mike Sondalini Free book sample - Contents - Back to Review The free online ebook sample below is copyright protected. You may not modify, publish, transmit, display, participate in the transfer or sale, create derivative works, or in any way exploit, any of the free online ebook sample content, in whole or in part.

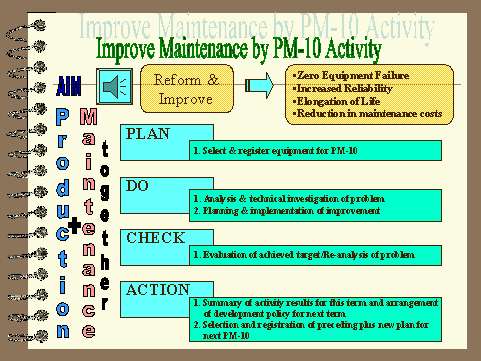

A systematic method of equipment reliability improvement is adopted. It is based on the well-proven quality management 'Plan - Do - Check - Action' self-improvement approach. Consultation between Production and Maintenance Departments produces the PM-10 (Preventing Maintenance over 10 years) plan of production equipment to be investigated for improvement. The operating problems are scrutinized and analyzed and then corrective plans are put into place. The improvement work is designed, organized and scheduled. The improvement may be a design-out, a process change or a simple procedural change. Continuous improvement was the normal way of thinking and living in this Japanese company. Once the change is in place it is again evaluated against the originally intended aims. If the original problem has not been solved satisfactorily the issue is again reviewed. The plan for future improvement work is adjusted if further progress is needed on the problem. The continuous improvement method is followed until the equipment problems are considered to be unimportant enough to be left off the PM-10 plan. Continued in "The Maintenance War" ebook ...

Price: US$

|

The Japanese Path To Maintenance Excellence.By Mike Sondalini Free book sample - Contents - Back to Review The free online ebook sample below is copyright protected. You may not modify, publish, transmit, display, participate in the transfer or sale, create derivative works, or in any way exploit, any of the free online ebook sample content, in whole or in part.

A systematic method of equipment reliability improvement is adopted. It is based on the well-proven quality management 'Plan - Do - Check - Action' self-improvement approach. Consultation between Production and Maintenance Departments produces the PM-10 (Preventing Maintenance over 10 years) plan of production equipment to be investigated for improvement. The operating problems are scrutinized and analyzed and then corrective plans are put into place. The improvement work is designed, organized and scheduled. The improvement may be a design-out, a process change or a simple procedural change. Continuous improvement was the normal way of thinking and living in this Japanese company. Once the change is in place it is again evaluated against the originally intended aims. If the original problem has not been solved satisfactorily the issue is again reviewed. The plan for future improvement work is adjusted if further progress is needed on the problem. The continuous improvement method is followed until the equipment problems are considered to be unimportant enough to be left off the PM-10 plan. Continued in "The Maintenance War" ebook ...

Price: US$

|

|

|

|